Power Electronics

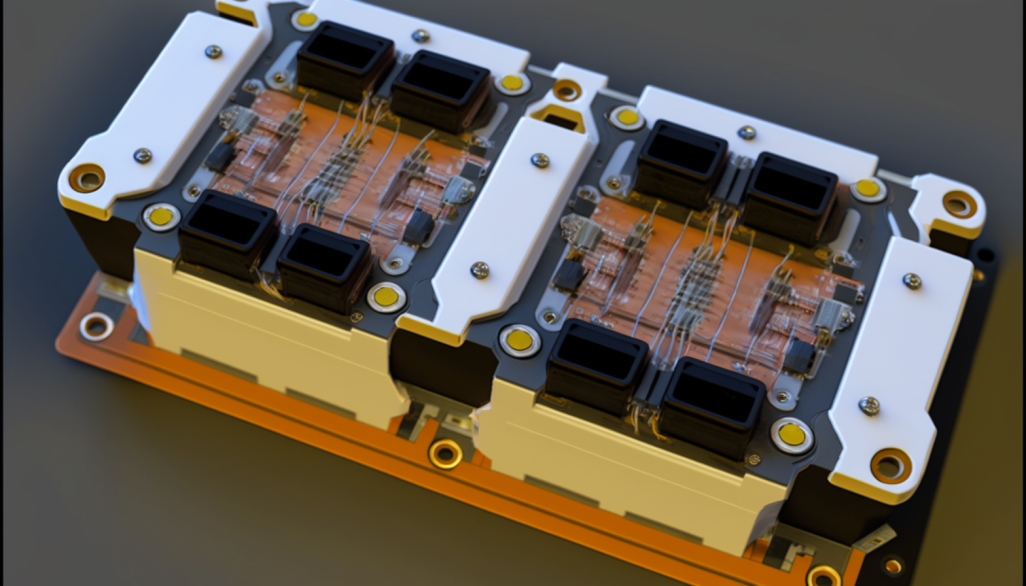

Power electronics has become crucial to modern technology, propelling growth in renewable energy, electric vehicles, and consumer electronics. Achieving high power density, efficiency, and long lifespan in power electronics requires materials with high thermal conductivity and reliability, such as metalized ceramics.

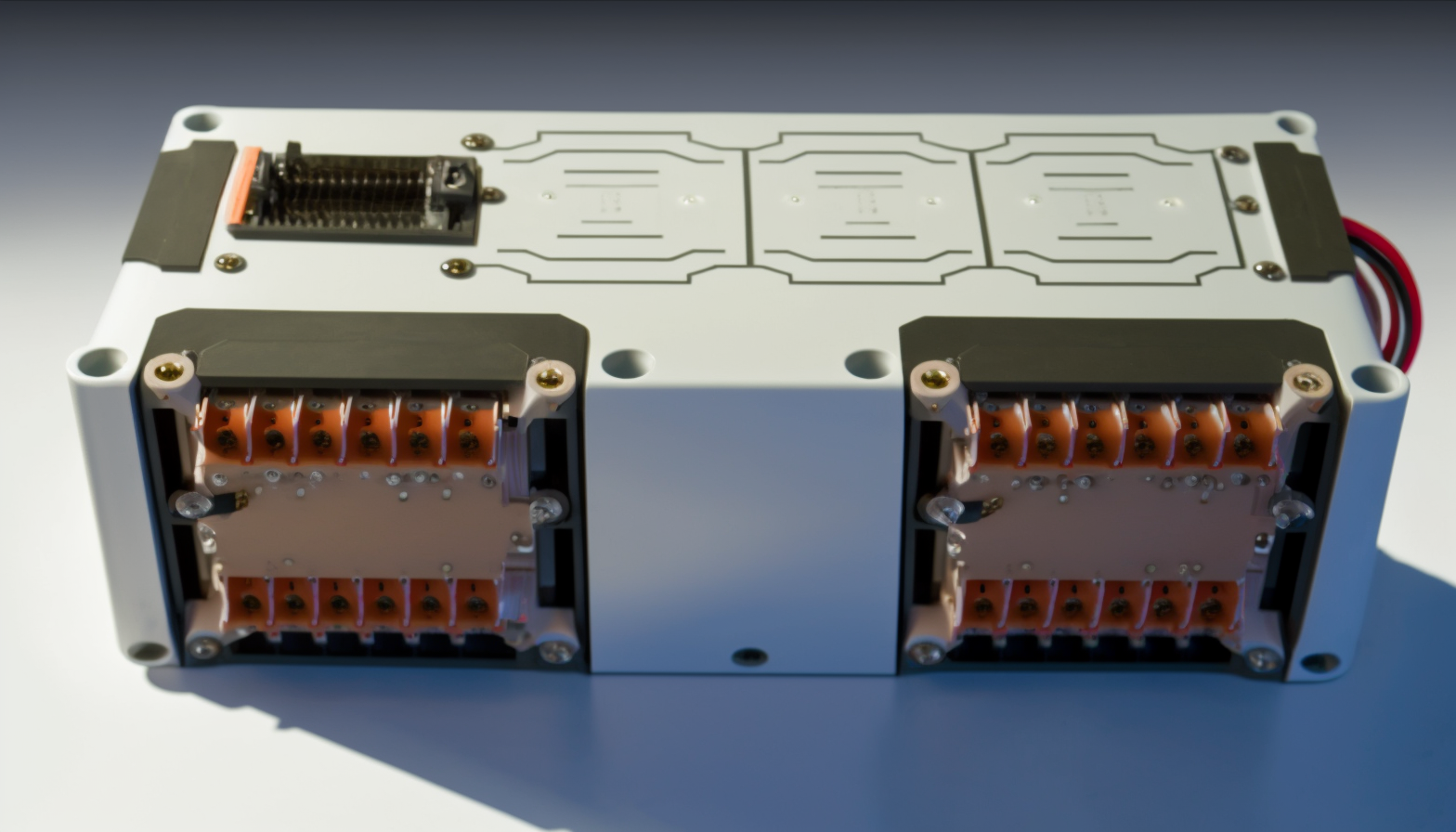

Metalized ceramics are ceramic materials coated with a metal layer, providing a conductive surface for electronic components. Ceramic substrates with metalized layers offer excellent thermal conductivity and mechanical strength, ideal for high power density designs. Braze solutions are used to join metalized ceramics to other materials like copper and aluminum, typically consisting of silver-based alloys with high melting points and good wetting properties like AgCu.

The use of metalized ceramics and braze solutions in power electronics provides several benefits, including efficient heat dissipation, high reliability and long lifespan, and the design of smaller and more efficient power electronics systems. With the growing demand for efficient and reliable power electronics, the use of metalized ceramics and braze solutions will continue to be critical in the future.

Benefits of Metalized Ceramics and Braze Solutions in Power Electronics

Metalized ceramics and braze solutions offer several advantages in power electronics, making them a popular choice for various applications. One major advantage is their ability to provide efficient heat dissipation from electronic components. The high thermal conductivity of metalized ceramics and the use of brazes with good wetting properties ensure that heat generated by the components is quickly dissipated, preventing overheating and damage to the system.

Another advantage of metalized ceramics and braze solutions is their high reliability and long lifespan. Ceramic substrates with metalized layers are mechanically stable and offer excellent resistance to thermal and mechanical stress. The bonding strength of brazes is also exceptional, ensuring that the joints remain secure and durable even in harsh environments. This high reliability is crucial in power electronics, where failure can lead to costly downtime and safety hazards.

Finally, the use of metalized ceramics and braze solutions enables the design of smaller and more efficient power electronics systems. The high thermal conductivity and mechanical strength of ceramic substrates with metalized layers allow for high power density designs, reducing the size and weight of power electronics systems. This, combined with the excellent bonding strength and electrical conductivity of brazes, enables the creation of more compact and efficient electronic devices.

Power Electronics

The application of metalized ceramics and braze solutions is essential in achieving high thermal conductivity and reliability in power electronics. The use of these materials enables the design of high power density devices that are smaller, more efficient, and more reliable. With the growing demand for efficient and reliable power electronics in various industries, metalized ceramics and braze solutions are likely to become even more critical in the future.