Share

The Versatility and Durability of High Purity Alumina Ceramics

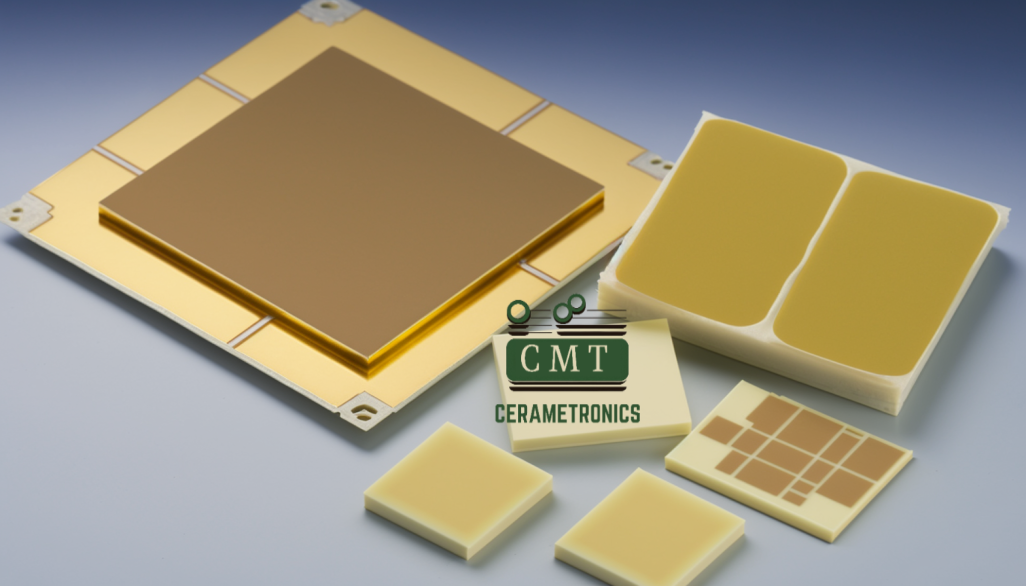

High purity alumina is a widely used advanced ceramic material with exceptional physical and chemical properties, including high chemical stability and resistance to harsh environments such as high temperatures, strong acids, and strong bases. Cerametinics, a leading manufacturer of advanced ceramic materials, offers high purity alumina ceramics of exceptional quality that can provide customized shapes and sizes to meet specific customer needs.

The production process of high purity alumina involves several steps, including powder preparation, shaping, sintering, and processing. Powder preparation typically uses alumina powder as raw material, followed by shaping using methods such as pressing, injection molding, or extrusion. The ceramic bodies are then sintered in a high-temperature furnace to create a dense structure and enhance their hardness and corrosion resistance. Finally, processing and surface treatment processes are performed to achieve the required precision and surface requirements for high purity alumina.

High purity alumina ceramics possess outstanding insulation properties, including low dielectric constant and dielectric loss, making them highly effective in high-frequency signal transmission. They are widely used in the manufacturing of high-frequency and high-precision instruments such as high-frequency filters, RF windows, antenna bases, and microwave integrated circuits in the communication and electronics fields. Additionally, high purity alumina is also used in the semiconductor and optoelectronics industries to manufacture high-precision mechanical bearings, thermocouples, and infrared sensors.

The biocompatibility of high purity alumina is also crucial in the manufacture of medical devices and artificial bones. Due to its excellent biocompatibility, low wear, and corrosion resistance, high purity alumina can be used to manufacture various types of medical devices and artificial bones. In the manufacture of artificial bones, high purity alumina can replace traditional metal materials, reducing the release of metal ions and providing better mechanical strength and biocompatibility.

Cerametinics is committed to the research and development of cutting-edge materials and processes for high purity alumina ceramics, adhering to the philosophy of “quality first and innovation development.” The company has established a strict quality control system, including quality monitoring and inspection of raw materials, powder preparation, shaping, sintering, and processing. Additionally, Cerametinics provides professional customer service and technical support to help customers solve problems in material applications and processing, providing the best solutions and recommendations.

In conclusion, Cerametinics’ high purity alumina ceramic products have a wide range of applications and market demand. Their commitment to quality control and customer service, along with advanced manufacturing processes, ensures that their high purity alumina ceramic products meet the strictest quality standards and provide optimal performance. With the ongoing advancement of technology, the demand for high purity alumina ceramics is expected to continue to grow, and Cerametinics is well-positioned to meet the needs and challenges of its customers in various industries.

High purity alumina ceramics

The Advantages of High Purity Alumina Ceramics by Cerametinics

High purity alumina ceramics are an improved version of 99 alumina ceramic, with a purity level of 99.99% or higher. This improved purity level enhances the material’s properties, including electrical insulation, high-temperature strength, wear resistance, and corrosion resistance. Additionally, high purity alumina ceramics possess high mechanical strength, high thermal conductivity, and excellent biocompatibility, making them suitable for various advanced applications.

Cerametinics uses advanced manufacturing processes to produce high purity alumina ceramics of the highest quality, available in various shapes and sizes with high uniformity and stability, to meet the specific needs of different customers. The production process of high purity alumina ceramics follows the same steps as 99% alumina ceramics, including powder preparation, shaping, sintering, and processing. However, the purity of the raw materials and the precision of the production process are much higher in high purity alumina ceramic production, resulting in a more advanced and refined product.

High purity alumina ceramics have a wide range of applications in various industries, including high-precision instruments, electronics, semiconductor, aerospace, and medical industries. In the semiconductor industry, high purity alumina ceramics are used to manufacture a range of components, such as IC packages, laser components, and high-temperature furnace components. In the aerospace industry, high purity alumina ceramics are used to manufacture components that require high strength, wear resistance, and high-temperature stability.

In the medical industry, high purity alumina ceramics are used to manufacture various types of medical devices and artificial bones due to their excellent biocompatibility, low wear, and corrosion resistance. High purity alumina can replace traditional metal materials in the manufacture of artificial bones, reducing the release of metal ions and the impact on the human body while providing better mechanical strength and biocompatibility.

Cerametinics’ commitment to quality control and customer service, along with its advanced manufacturing processes, ensures that their high purity alumina ceramic products meet the strictest quality standards and provide optimal performance. With the ongoing advancement of technology, the demand for high purity alumina ceramics is expected to continue to grow, and Cerametinics is well-positioned to meet the needs and challenges of its customers in various industries.

High purity alumina ceramics

In conclusion, high purity alumina ceramics are an advanced ceramic material that possesses excellent physical and chemical properties, making it suitable for various advanced applications. Cerametinics’ high purity alumina ceramic products are of exceptional quality and provide customized solutions to meet specific customer needs. With a focus on quality control and customer service, Cerametinics continues to provide innovative solutions to meet the evolving needs and challenges of their customers. To learn more about Cerametinics’ high purity alumina ceramics and services, visit our website at www.ceramet.ca.

Let’s Keep In Touch

I look forward to hearing from you!

STAY IN THE LOOP

Subscribe to our free newsletter.

The Role of CHATGPT and AI in Advancing Metal-Ceramic Materials: Specifically with Cerametronics Introduction CHATGPT and other AI technologies are contributing to the advancement of metal-ceramic materials in industries such as material science. Specifically, we will discuss the impact on Cerametronics as a leading producer and supplier of high-performance ceramic components for extreme environments. What […]